Excellence Logging is a specialist oilfield services company with focused competence in Surface Data Logging and Light Well Intervention services. We provide customers with safe and technically advanced reservoir fluid and geological formation evaluation, drilling monitoring, slickline, electric line, light coiled tubing, and data consulting services. Formed in 2015, Excellence Logging benefits from an experienced management team, innovative research and engineering, and a collaborative approach to meeting customer needs.

We are committed to promote policies and systems to ensure we monitor all aspects of our corporate social responsibility program as it pertains to our business. We place particular focus on strong ethical behavior, deep concern for employee and contractors’ health and safety, and care for the environment and the communities in which we work. We also identify and assess the risks associated with our activities and we ensure that appropriate mitigation and control measures are in place.

Exploration Logging Management requires proactive commitment, leadership, accountability and planning from all employees, suppliers, contractors, sub-contractors, agents, and other interested parties working under its responsibility.

Health, Safety, Environment, Quality, Business Ethics, Security, and Business Continuity are all integral elements of the Excellence Logging Integrated Management System (IMS). Our goals are to: comply with all relevant health & safety standards in the countries where we operate; protect the environment through best environmental practices; achieve and maintain excellence in all quality aspects to continuously meet or exceed customer expectations; develop and sustain an irreproachable ethical behavior in every country in which we conduct business; and optimize security (including cybersecurity) to minimize exposure of personnel, assets, and information to potential threats.

We encourage and support initiatives that prevent adverse effects in our activities and improve our IMS. All relevant resources are provided to deliver products and services in compliance with our policies and with all applicable laws, regulations or standards.

Excellence Logging Policies are revised regularly to ensure they are coherent with corporate strategy. They provide the framework for setting attainable objectives and performance is monitored to improve the effectiveness of the Excellence Logging Integrated Management System.

John LECHNER

Chief Executive Officer

Excellence Logging

Focused Competence Operating Management System

Excellence Logging Management System is based on the guidelines for the development and application of the Health, Safety and Environmental Management systems (OGP 510 and 511) of the International Association of Oil and Gas Producers and IPIECA. These documents define the elements by which we will conduct our operations worldwide in order to protect our personnel, the public, and the environment within which they work and live.

Applicability of the Excellence Logging Management System is clearly defined. Our Management System applies whenever Excellence Logging has direct management control of activities. Whenever activities are not directly managed by Excellence Logging, risks must always be managed at the appropriate level. This is particularly important when working in partnerships with contractors, subcontractors, suppliers, and other third parties, or when collaborating with local communities.

The ten interrelated Elements of the Management System with underlying expectations are:

- Leadership, Commitment & Accountability

- Policy, Standards & Objectives

- Organisation, Resources & Capability

- Stakeholders, Customers & Local Communities

- Risk Assessment & Control

- Asset Design & Integrity

- Plan & Procedures

- Execution of Activities

- Monitoring, Reporting & Learning

- Assurance, Review & Improvement

Our Logging Management System is driven by the “Plan, Do, Check & Act” concept.

- PLAN to clarify the objectives of the activity and organize appropriate resources. Engage all parties involved or affected. Ensure risks are identified and measures defined to eliminate them. Remaining risks are assessed to define appropriate controls or mitigation.

- DO to execute and control the activity based on plans and procedures, including those to manage risks.

- CHECK to Monitor and ensure plans and procedures are being followed and to confirm risk controls / barriers are effective. Measure progress and assess for improvement opportunities and / or assurance.

- ACT to review outcomes and performance. Establish improvement action, incorporate into (future) plans for the activity and embed relevant learning in the OMS.

- John LECHNER

Chief Executive Officer

Excellence Logging Response in Coronavirus Times

The Coronavirus outbreak was declared a Public Health Emergency of International Concern on 30 January 2020 by the World Health Organization (WHO). Excellence Logging immediately prepared precautionary advice before governments made their own calls to limit the spread of COVID-19. The Coronavirus sanitary crisis is spreading around the world and presses us every day to act quicker. Excellence Logging is firmly and vigorously addressing these unprecedented circumstances throughout the whole organization.

Our engagements:

- At high level, a Situation Response Team including HSEQ & Security, Human Resources, Operations and Supply Chain departments has been activated to deal daily with information and strategies to ensure the safety and wellbeing of our personnel; manage messages and communications to our employees and any other interested parties; and monitor and mitigate threats to our global business.

- Our Global Travel Restrictions Directive has been drawn up and is applicable from February 25th with assessment and management approval required from Vice Presidents or Senior Executives.

- Work from home has been prescribed wherever and whenever possible and for the foreseeable future, with sharing of best practices, for both employees and managers, on how to be productive in your home office, or how to lead teams remotely and ways to keep employees engaged and committed.

- Excellence Logging's business travel insurance training is provided to every personnel concerned by travelling overseas.

- Common Questions and Answers on COVID-19 is being distributed throughout the organization to increase education and knowledge and provide guidance to the staff working both at well sites and in the office, or from home.

- Regular communications and alerts are made across the Excellence Logging organization in all regions, with useful links to official websites and multiple expert resources. Periodic advice and tips are given to prevent the spread and transmission to field locations and offices, inclusive of awareness, symptom recognition, prevention methods, precautionary measures and travel restriction information with regard to COVID-19.

- Advice of relevant national health authorities is strictly adhered to in every country where we operate.

- New processes are in place to help protect our employees and at the same time respect our customers protocols (quarantine, travel, pre-mobilization and health checks, worksite access, medical evacuation interface, social distancing and isolation).

- Base and rig site monitoring is actively implemented.

- Specific local COVID-19 Emergency Response/Medevac Plans have been defined in all regions with current operations.

- Business continuity plans are in place to make sure we do not interrupt the services our customers need.

- Worldwide Coronavirus daily summaries are diffused to Senior and Executive Management

(sources: https://www.internationalsos.com/; www.who.int/emergencies/diseases/novel-coronavirus-2019; - Novel Coronavirus (COVID-19) Infection Map GLOBAL TREND: https://hgis.uw.edu/virus/ ).

Any concern on the COVID-19 please contact covid19@exlog.com

Awards and Certifications

Excellence Logging holds a range of certifications and awards which validate our capabilities in multiple key areas.

Oil & Gas Awards 2018

As Excellence Logging continues to grow, our employees are a critical aspect of who we are as an organization considering they represent our brand, values and that they drive our organization through innovation.

The ISO 9001:2015 certificate for DHI Services Sdn. Bhd., an Excellence Logging Company, has been successfully renewed.

The management system of DHI Services Sdn, Bhd., an Excellence Logging Company, has been assessed by ABS Quality Evaluations, Inc. and found to be in conformance with the requirements set forth by ISO 9001:2015. Our Quality Management System is applicable to operation, manufacturing, refurbishment and service support of surface data logging units.

Mr Yves Gehan, Vice President for Excellence Logging in Asia said : "We are proud to achieve the re-certification of ISO 9001:2015 for another two years under the Excellence Logging (EXLOG) Group. Perfection is not attainable, but if we chase perfection, we can deliver Excellence. Excellence in high level of reliability, competence delivery, delivery of quality and delivery of satisfying solutions to problems."

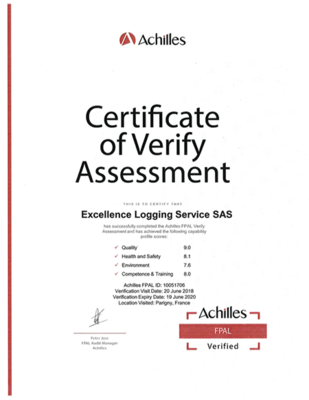

FPAL ASSESSMENT CERTIFICATE EXCELLENCE LOGGING SERVICES

ISO 9001:2015 CERTIFICATE EXCELLENCE LOGGING SERVICES

Excellence Logging Services has been certified ISO9001 for15 years. It's ISO 9001-2015 certificate has been re-assessed and is now valid until November 29th, 2019.

ISO 9001 & ISO 14001 Certificates

Dajan East srl extended its Well Intervention ISO 9001 and the Surface Data Logging ISO 14001 certificates.

This achievement certifies the high quality and care for environmental delivered by Dajan East.

“I am very proud that Dajan East, thanks to the merger with the Excellence Logging group, is beginning surface data logging services in Eastern Europe in 2018 by participating in new tenders in Romania” said Gianfranco Protano, Dajan East Region Manager.

UNI EN ISO 9001:2015 and UNI EN ISO 14001 certified

Dajan, an Excellence Logging Company, is an Italian-registered UNI EN ISO 9001:2015 and UNI EN ISO 14001 certified service company mainly specialized in the delivery of services and products related to slickline, wireline, coiled tubing and production enhancement systems. Dajan performs operations both on land and offshore on either gas or oil wells with surface equipment that can withstand operating pressures up to 15,000 psi.

Dajan implemented the following Management and Safety systems in order to initiate any action aimed at protecting not only the health and safety of human resources but also with respect to the environment in which it operates:

Quality Management System according to UNI EN ISO 9001: 2015

Environmental Management System prepared according to UNI EN ISO 14001

Risk Assessment according to the Decree. No. 81/2008

Safety Manual according to the Decree. No. 624/96

Dajan always actively participates and collaborates with customers to comply with safety regulations. In particular, equipment checks are first planned and then carried out either in or outside our facilities. These are all recorded in the test report that has the dual purposes of highlighting the efficiency of equipment and updating the track record.

Dajan's staff is the key to ensure respect of both legislative and operational requirements and its people are regularly trained and informed of any and all job safety aspects. All operations are supervised by managers or officers that guide employees in operating safely and in compliance with Dajan and customer internal regulations. All field personnel are equipped with appropriate personal protective equipment (PPE) and trained to use them consistently and correctly. The company holds periodic meetings designed to allow the disclosure and the exchange of information and constructive cooperation between all company teams.